Material Test Labs: Your Partner in Screening

Unveiling the Keys of Products: Bespoke Testing Solutions for Industries

Are you interested about the tricks that materials hold? Do you intend to reveal the hidden possibility of the products made use of in numerous markets? Look no more. In this short article, we will certainly discover bespoke screening services that can aid you unravel the mysteries of materials. Discover the relevance of products screening and the various solutions offered to fulfill your specific demands. We will additionally explore vital elements to take into consideration and showcase successful situation researches. Prepare yourself to open the secrets of products!

The Importance of Materials Screening in Industries

You require to comprehend the significance of materials screening in sectors to ensure the top quality and reliability of your products. Materials screening plays an essential function in numerous industries, such as manufacturing, building, aerospace, vehicle, and medical care. By subjecting materials to rigorous screening, you can ensure that they fulfill the called for requirements and specs.

One of the essential reasons that products testing is essential is to make sure the safety of your items. Whether you are producing a vehicle, building a bridge, or developing a clinical tool, the products used must have the ability to withstand the desired conditions and carry out as expected. Via testing, you can determine any kind of weak points or flaws in the materials, allowing you to make needed enhancements or changes prior to the items reach the marketplace.

In addition to security and efficiency, materials screening likewise aids in top quality control. By conducting tests at various phases of the manufacturing process, you can determine any type of variances or disparities in the materials being made use of. This permits you to take corrective actions and make sure that the end products satisfy the desired high quality standards.

Types of Materials Testing Providers Available

There are numerous types of products evaluating solutions that are available for different industries. Whether you remain in the building, aerospace, or manufacturing market, there specify tests that can aid make certain the high quality and safety and security of your products.

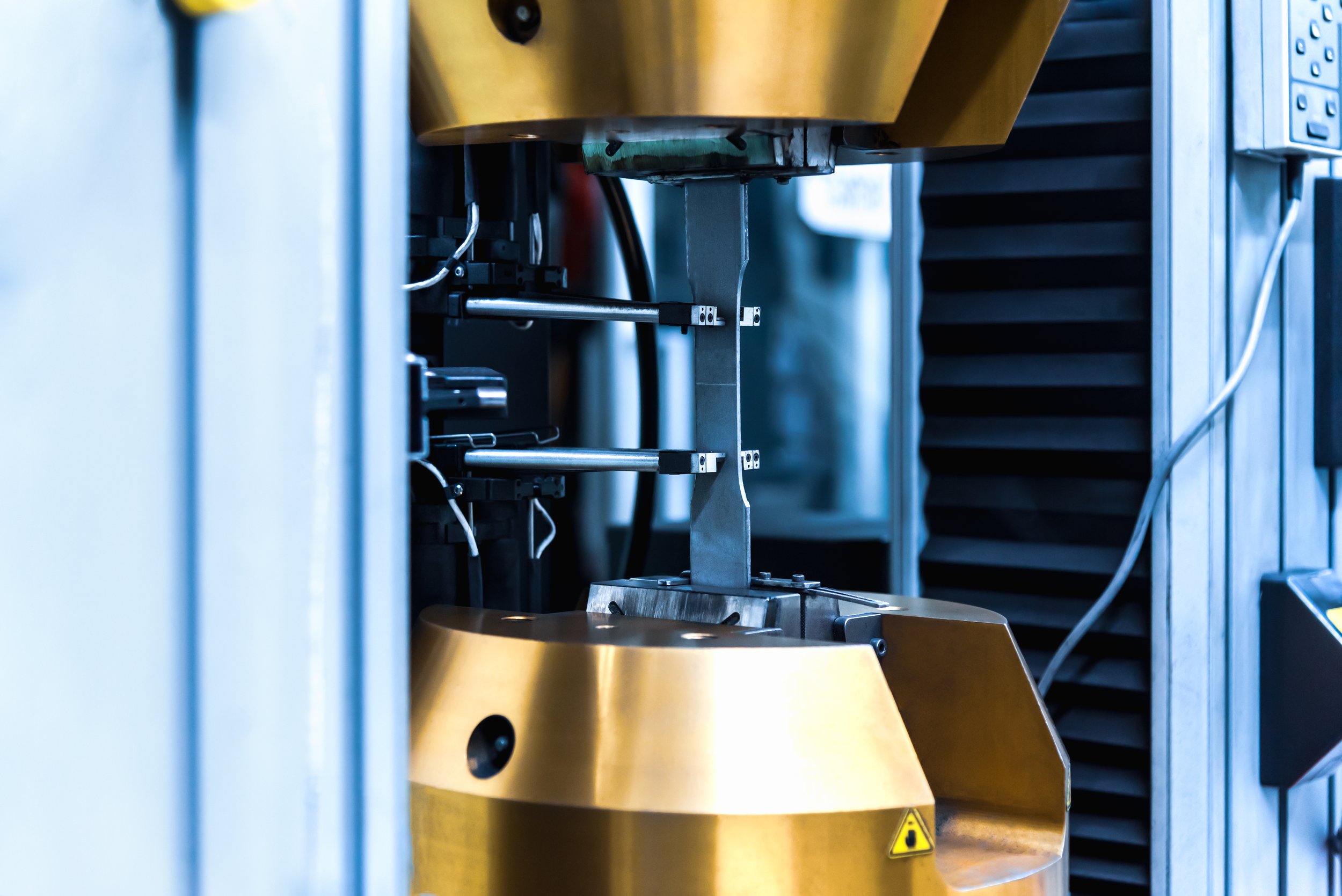

One common kind of products testing service is mechanical testing. This entails evaluating the mechanical properties of a material, such as strength, hardness, and elasticity. By carrying out examinations like influence, tension, and compression examinations, you can determine if a material satisfies the needed requirements for your industry.

Another important screening service is chemical analysis. This involves examining the composition of a material to recognize the existence of specific aspects or compounds. Chemical evaluation can help make certain that a material is devoid of hazardous compounds or pollutants that may influence its performance or present a risk to individuals.

Physical screening is likewise important in products screening. This includes evaluating the physical properties of a material, such as density, conductivity, and thermal development. By conducting physical tests, you can figure out if a product has the desired qualities and if it can withstand the conditions it will be exposed to in your industry.

In addition to these sorts of testing solutions, there are likewise specialized tests readily available for particular markets. The vehicle industry might require products examining for factors such as rust resistance or exhaustion toughness.

Total, materials screening services play a crucial role in ensuring the high quality and integrity of materials made use of in numerous markets. By making use of these solutions, you can believe in the products you use and make sure the success of your jobs.

Key Variables to Think About in Bespoke Testing Provider

When considering bespoke screening solutions, it's crucial to take into account crucial official statement factors that can influence the top quality and reliability of the tests carried out. You desire to make sure that the professionals carrying out the tests have the essential knowledge and abilities to accurately analyze the products being evaluated. By thinking about these key aspects, you can make sure that the bespoke testing solutions you select will certainly supply you with exact, reputable, and timely results.

Study: Effective Applications of Products Testing

In the auto market, products testing has played a crucial function in ensuring the safety and efficiency of vehicles. From examining the resilience of engine parts to evaluating the toughness of products utilized in the body, materials testing has actually aided to ensure and prevent catastrophic failings traveler safety and security. Additionally, check this products testing has been applied in the building sector to guarantee the architectural stability of buildings and framework.

Future Trends in Products Testing for Industries

In the future, markets will increasingly rely upon innovative materials testing techniques to guarantee the top quality and efficiency of their items. As innovation remains to breakthrough, so does the requirement for much more innovative testing techniques. By utilizing these innovative methods, industries can get valuable insights into the homes and actions of their products, enabling them to make enlightened decisions and boost their items.

One such technique that will certainly see substantial growth in the future is non-destructive screening. This approach allows for the analysis of products without causing damage, making it optimal for markets that call for the reuse or retesting of materials (material test labs). By using non-destructive testing, companies can conserve time and sources while still making sure the dependability and security of their products

An additional fad that will certainly form the future of products testing is using expert system and device knowing. These modern technologies have the potential to reinvent the screening procedure by automating information analysis and interpretation. By making use of AI and maker knowing formulas, sectors can rapidly and precisely determine any flaws or weak points in their products, enabling them to take positive steps to resolve these concerns.

Furthermore, the future will certainly see a boosted concentrate on sustainability in materials screening. Industries will seek to develop testing techniques that minimize waste and ecological effect - material test labs. This consists of using green screening approaches and the expedition of alternate materials that are extra environmentally pleasant and lasting

Conclusion

In verdict, products screening plays a crucial duty in industries by making certain the quality, reliability, and safety and security of materials made use of in various applications. With a broad range of testing services readily available, customized specifically to satisfy market needs, business can acquire useful insights right into the residential properties and performance of their materials. By taking into consideration essential factors such as cost-effectiveness, efficiency, and accuracy, bespoke testing solutions can provide accurate and reputable outcomes. As markets continue to develop, future trends in products screening will likely concentrate on innovative methodologies and sophisticated modern technologies to fulfill the growing needs click to investigate of the market.

Physical testing is likewise crucial in products testing. From evaluating the longevity of engine parts to assessing the stamina of materials utilized in the fuselage, materials screening has actually aided to stop disastrous failures and ensure passenger safety and security.In the future, industries will progressively count on innovative products screening methods to make sure the quality and performance of their products.In final thought, materials screening plays a vital role in industries by making certain the quality, reliability, and safety and security of materials utilized in different applications. As sectors continue to evolve, future patterns in materials testing will likely focus on ingenious approaches and sophisticated innovations to meet the growing needs of the sector.